Learn about Car Battery Replacement

Outline:

– How car batteries work, lifespan, and warning signs

– Choosing a replacement by size, ratings, and chemistry

– Tools, safety, and preparation before you start

– Step-by-step replacement and post-install checks

– Costs, maintenance, and responsible recycling

How Car Batteries Work and When Replacement Is Due

Think of your car battery as the quiet starter of every journey: it energizes the starter motor, feeds the ignition system, and buffers power for lights, infotainment, and safety modules. Most passenger vehicles rely on a 12‑volt lead‑acid design where chemical reactions between lead plates and an electrolyte store and release energy. Over time, heat, vibration, and charge cycles wear down the active material on the plates, gradually reducing capacity. In typical daily driving, a conventional flooded lead‑acid battery often lasts about 3–5 years, though climate and usage can shorten or extend that window. High heat accelerates corrosion; deep discharges (like leaving lights on) speed up sulfation; short trips can starve the battery of a full recharge.

You don’t need special intuition to spot warning signs. Watch for these clues that a replacement may be due:

– Slow or labored cranking, especially after the vehicle sits overnight.

– Dashboard warning lights or erratic electrical behavior under load.

– Dimming headlights at idle that brighten with engine speed.

– Clicking from the starter solenoid instead of a steady crank.

– Repeated jump-starts needed within a short period.

These symptoms can overlap with alternator or starter problems, so testing helps separate the suspects.

A simple multimeter offers quick insight. After the car rests several hours, a healthy, fully charged battery typically reads around 12.6 V (approximately 100% state of charge). Rough guideposts: ~12.4 V is near 75%, ~12.2 V near 50%, and below 12.0 V indicates a deep discharge. During cranking, voltage commonly should not dip below roughly 9.6 V at moderate temperatures; a much lower sag may hint at weak cells or internal resistance growth. For a more complete picture, a conductance or load test evaluates the battery’s ability to deliver current, and a charging-system check confirms the alternator brings voltage to about 13.8–14.7 V with the engine running and accessories on. When testing reveals declining capacity or when age and symptoms align, planning a timely replacement prevents inconvenient no‑start surprises.

Selecting the Right Replacement: Size, Ratings, and Chemistry

Choosing a replacement battery is like fitting a new heart into an electrical ecosystem—dimensions, strength, and compatibility all matter. Start with physical fitment. Battery group size (often specified in the owner’s manual) defines case dimensions and terminal layout; choosing the correct group avoids strained cables and ensures the hold‑down clamps secure the case firmly, reducing vibration damage. Terminal orientation varies by design, so match positive and negative post positions to your vehicle’s cables. In some models, especially those with trunk or interior batteries, a vent tube connects to the case to route gases outside the cabin; if your original battery had a vent, the new one needs compatible ports.

Next, focus on performance ratings. Cold cranking amps (CCA) indicate the current a battery can deliver at 0°F/−18°C for 30 seconds while maintaining adequate voltage; higher CCA is useful in cold climates where oil thickens and engines demand more starting power. Reserve capacity (RC) or amp‑hour (Ah, more common on absorbed glass mat batteries) reflects how long the battery can support electrical loads if the alternator is not charging—helpful during long accessory use with the engine off. Aim to meet or modestly exceed the original equipment ratings; massive overkill adds cost without meaningful everyday benefits, while undershooting can lead to weak starts and short life.

Chemistry matters, too. Common options include:

– Flooded lead‑acid: cost‑effective, time‑tested, suitable for many vehicles without start‑stop.

– Enhanced flooded (EFB): upgraded durability for frequent restarts and higher accessory loads.

– Absorbed glass mat (AGM): spill‑resistant, vibration‑tolerant, charges efficiently, favored in start‑stop or high‑electrical‑demand vehicles.

– Lithium 12 V systems: light and powerful but require precise charging control; not typical on mainstream vehicles and may not be compatible.

If your car uses start‑stop technology or lists AGM/EFB from the factory, avoid downgrading chemistry; the charging strategy and electrical architecture are tuned for the specified type.

Round out your selection by checking date codes (fresher is better), warranty terms (as a quality signal rather than a promise of lifespan), and climate. A final pre‑purchase checklist helps:

– Confirm group size, terminal orientation, and venting needs.

– Match or exceed CCA and RC (or Ah) to factory specs.

– Choose the chemistry type specified by the manufacturer.

– Verify the battery is recent and fully charged at purchase.

With the right fit and ratings, you set yourself up for reliable starts and stable electrical performance.

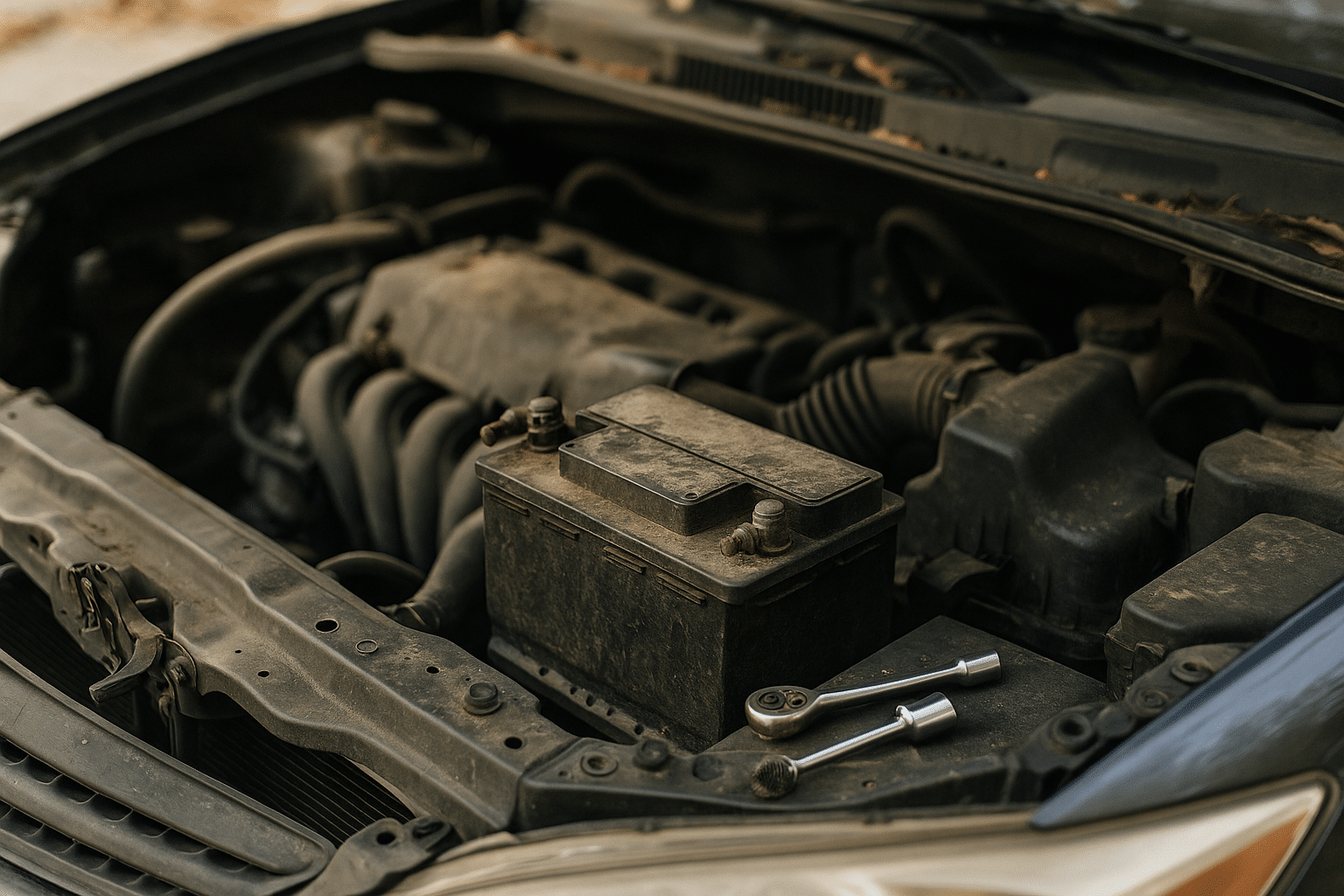

Preparation, Tools, and Safety You Should Not Skip

Before you loosen a single clamp, set the scene for a calm, clean, and safe replacement. Park on a flat surface, engage the parking brake, turn off all accessories, and remove the key or switch off the start button. Allow hot engine components to cool. Keep a window cracked or the hatch open in case auto‑lock features engage when power is interrupted. If your vehicle requires radio or infotainment security codes after power loss, locate those ahead of time. Some modern cars include a battery sensor on the negative terminal; take care not to strike or stress this component.

Gather tools and supplies so you’re not rummaging mid‑job:

– Socket set and wrench (common terminal fasteners are small; extensions help with hold‑downs).

– Battery strap or lifting handle to move the heavy case safely.

– Safety glasses and chemical‑resistant gloves to protect from acid and corrosion dust.

– Baking soda and water to neutralize small acid residues, plus paper towels or shop rags.

– Terminal brush or mild abrasive pad for cleaning posts and clamps.

– Dielectric grease or terminal protectant to help resist future corrosion.

– A memory saver (optional) to maintain settings during the swap.

Position a sturdy box or mat to set the old battery down vertically; tipping can promote spills in non‑sealed designs.

Safety is not a formality here; it’s crucial. Lead‑acid batteries can vent hydrogen gas during charging; avoid sparks and open flames. Remove metal jewelry, which can bridge terminals if it contacts posts and chassis. Work one cable at a time, starting with the negative clamp; this reduces the chance of shorting a wrench from the positive post to ground. Keep tools clear of painted surfaces to avoid scratches, and be mindful of plastic trim that can crack in cold weather. Neutralize any white or blue corrosion fuzz around terminals with a baking‑soda solution, rinse carefully, and wipe dry. Finally, inspect the hold‑down hardware and the tray: loose or rusty brackets can let the battery shift, fatiguing cables and shortening its life. Ten minutes spent on preparation often saves an hour of frustration later.

Step-by-Step Replacement and Post-Install Checks

With the stage set, the swap proceeds smoothly. Start by taking a quick reference photo of the existing setup—cable routing, hold‑down position, and any vent hoses. If you’re using a memory saver, connect it per its instructions. Turn everything off again, then begin disconnection with the negative (−) terminal. Loosen the clamp enough to lift it straight up; tuck it aside so it can’t spring back into contact. Move to the positive (+) terminal and repeat. Next, remove the hold‑down bracket or strap; a long extension may help reach bolts tucked near the base. Lift the battery straight up using a strap or both hands, keeping it vertical.

With the battery out, clean the tray and hardware. Check for cracked plastic housings, frayed cable ends, and corrosion inside the clamps. A light scrub of the terminals and clamps improves electrical contact and reduces voltage drop. Position the new battery with the correct orientation—positive to positive cable side—and seat it flat in the tray. Reinstall and snug the hold‑down so the case cannot move; secure but not overly tight. Reconnect the positive (+) clamp first, then the negative (−). A thin smear of terminal protectant helps slow oxidation. Tighten until the clamp no longer rotates by hand; avoid overtightening, as battery posts are soft lead alloys. Reattach any vent tube if present and make sure it’s firmly seated.

Now verify that everything is behaving as expected. Turn the key or press start: the engine should crank briskly and settle into a steady idle. Run a simple charging‑system check with a multimeter:

– Engine off, rested battery: around 12.6 V when fully charged.

– Engine idling, minimal loads: typically 13.8–14.7 V.

– Engine idling, headlights and blower on: voltage should remain in the charging range without large drops.

If numbers are far outside these ranges, investigate alternator output, belt condition, and grounds.

Some vehicles need a short relearn period after power loss. You may notice a slightly unstable idle at first; allow the engine to idle in park for several minutes with major accessories off, then take a normal drive cycle so modules can recalibrate. Re‑set the clock and radio presets. On cars with one‑touch windows or sunroofs, reinitialize per the owner’s manual (often by holding the switch fully down and then fully up). After the first drive, open the hood and confirm the hold‑down is tight and the clamps are still secure. A quick visual once more the following day ensures nothing has shifted and that corrosion has not appeared.

Costs, Maintenance, and Recycling for the Long Run

Budgeting for a battery replacement is straightforward when you know the variables. Conventional flooded lead‑acid units commonly land in the range of roughly $100–$250 depending on size and ratings. AGM or EFB options, favored in start‑stop and high‑demand electrical systems, can run about $180–$400. Professional installation fees vary by region and access but often fall in a modest bracket, reflecting a short labor time for under‑hood units and longer time for trunk‑ or seat‑mounted configurations. Retailers typically apply a refundable core charge when you purchase a new battery; returning the old one for recycling credits that amount back to you and keeps hazardous materials out of landfills.

Smart care stretches the value of your purchase:

– Keep the battery firmly clamped; movement accelerates internal wear.

– Limit repeated short trips; combine errands or use a smart maintainer if the car sits.

– Turn off high‑draw accessories when the engine is off to prevent deep discharges.

– Inspect and clean terminals at service intervals; corrosion increases resistance and heat.

– Make sure the charging system is healthy; a weak alternator can silently drain the new battery’s lifespan.

If you store a vehicle for weeks, a low‑amp maintenance charger helps preserve charge without overcooking the cells.

Seasons deserve special attention. In summer, heat speeds up chemical aging—parking in shade or a garage helps. In winter, cold slows chemical reactions and thickens oil, demanding higher cranking current; ensuring the battery is fully charged before a cold snap can avert no‑start mornings. For vehicles that see both extremes, selecting a battery with ratings aligned to your climate pays dividends in confidence and longevity.

Finally, treat disposal as a responsibility, not an afterthought. Lead‑acid batteries are among the most successfully recycled consumer products, with recovery rates frequently exceeding 95% in many regions. The materials—lead, plastic, and electrolyte—are reprocessed into new batteries, reducing environmental impact and the need for raw extraction. Return the old unit where you purchased the new one or to authorized recycling centers; many auto parts retailers and municipal facilities accept them at no charge. Avoid at‑home disassembly or dumping; regulations in many areas prohibit landfilling and impose fines for improper handling. A careful choice, a clean installation, and conscientious recycling close the loop on a small job that delivers daily reliability.