Learn about Appliance Repair

Outline:

– Why Appliance Repair Matters: cost, safety, and sustainability

– Diagnose with Confidence: safety, tools, and common failures

– DIY Essentials: tools, parts, and step-by-step examples

– Repair vs Replace: a practical framework with numbers

– Hiring Help and Final Checklist: turning a plan into action

Why Appliance Repair Matters: Cost, Safety, and Sustainability

Every humming refrigerator, steady washer, and even the unassuming microwave plays a quiet role in your household economy. When one fails, the ripple touches your budget, schedule, and sometimes your safety. Repair is more than a quick fix; it’s a decision about resource use, energy consumption, and the lifespan of the machines that keep daily life flowing. Consider three pillars—cost, safety, and sustainability—when deciding how to respond to a breakdown, and you’ll avoid throwing money and materials at problems that a thoughtful plan could solve.

On cost: repairs often run a fraction of replacement, especially for issues like clogged filters, worn belts, or faulty sensors. Typical price ranges can help you set expectations before a technician ever arrives. While prices vary by region and model, household repair invoices commonly fall within these ballparks:

– Refrigerator issues like thermostat or defrost component replacement: roughly $120–$350

– Dishwasher pump, inlet valve, or door gasket: about $120–$400

– Washer belts, pumps, or lid switches: around $110–$300

– Dryer thermal fuses, igniters, or rollers: typically $90–$250

– Range or oven heating elements and sensors: approximately $120–$350

These figures are illustrative, not guarantees, but they underscore how a targeted fix can postpone a major purchase.

On safety: appliances mix electricity, heat, water, and moving parts. A shorted heating element in an oven risks shock; a cracked gas line can endanger occupants; a leaking washer invites mold and slip hazards. Routine maintenance—cleaning lint traps and dryer vents, inspecting hoses for bulges, and checking power cords—reduces these risks and can avert costly emergencies. Keep a working smoke detector and, where gas is present, a carbon monoxide alarm near key appliances.

On sustainability: extending the life of a functioning appliance reduces waste and the environmental footprint associated with manufacturing, packaging, and shipping new units. Typical lifespans offer context:

– Refrigerators: 10–15 years

– Dishwashers: 7–12 years

– Washers: 8–12 years

– Dryers: 10–13 years

– Electric ranges: 13–17 years

– Microwaves: 7–10 years

A minor midlife repair can prevent an early trip to the landfill. Pair that with energy-savvy maintenance—vacuuming refrigerator coils, keeping door gaskets clean, and leveling washers to reduce strain—and you gain measurable efficiency without a shopping spree.

Diagnose with Confidence: Safety, Tools, and Common Failures

Great repairs start with safe, systematic diagnostics. Before touching a screw, kill power at the plug or breaker and close water or gas valves as applicable. Wait for capacitors in microwaves and similar devices to discharge fully—these components can hold a charge even after unplugging. Wear cut-resistant gloves, use safety glasses, and maintain good footing on dry, uncluttered floors. A bright flashlight, a multimeter rated for household use, and a non-contact voltage tester are basic diagnostic companions that turn guesswork into observations.

Build a simple troubleshooting flow:

– Identify the symptom: no power, poor performance, leaks, noise, odor, error codes, or tripping breakers.

– Confirm supply: check the outlet with another device, verify breakers, inspect water supply hoses and shutoff valves, and ensure gas valves are open if applicable.

– Inspect accessible filters, lint traps, vents, and coils for blockages.

– Look and listen: rattles suggest loose fasteners or worn rollers; grinding hints at bearings; buzzing may indicate a stuck relay or failing capacitor.

– Use your multimeter to test continuity and voltage where safe and documented in the service manual.

Map common symptoms to likely causes to prioritize checks:

– Refrigerator warm but freezer cold: defrost failure, evaporator fan not running, or a blocked air duct

– Refrigerator short-cycling: dirty condenser coils, failing start device, or incorrect temperature settings

– Dishwasher leaving grit: clogged filter or spray arms, low water temperature, or worn wash pump

– Washer not draining: blocked drain filter, kinked hose, or failed drain pump

– Washer shaking or “walking”: unbalanced load, worn suspension rods, or shipping bolts never removed after delivery

– Dryer taking too long: clogged vent duct, crushed flex hose, or failed heating element/igniter

– Oven not reaching temperature: bad temperature sensor, failing element, or improper calibration

Document model and serial numbers—usually found on door frames, backs, or inner panels—before ordering parts. When error codes appear, consult the service sheet often tucked behind control panels or toe-kicks; it translates cryptic letters into specific checks. Take photos as you disassemble panels so reassembly is straightforward. If something feels unsafe or involves sealed systems, high-voltage capacitors, or gas lines, stop and plan for a qualified technician. Good diagnostics are decisive, not daring.

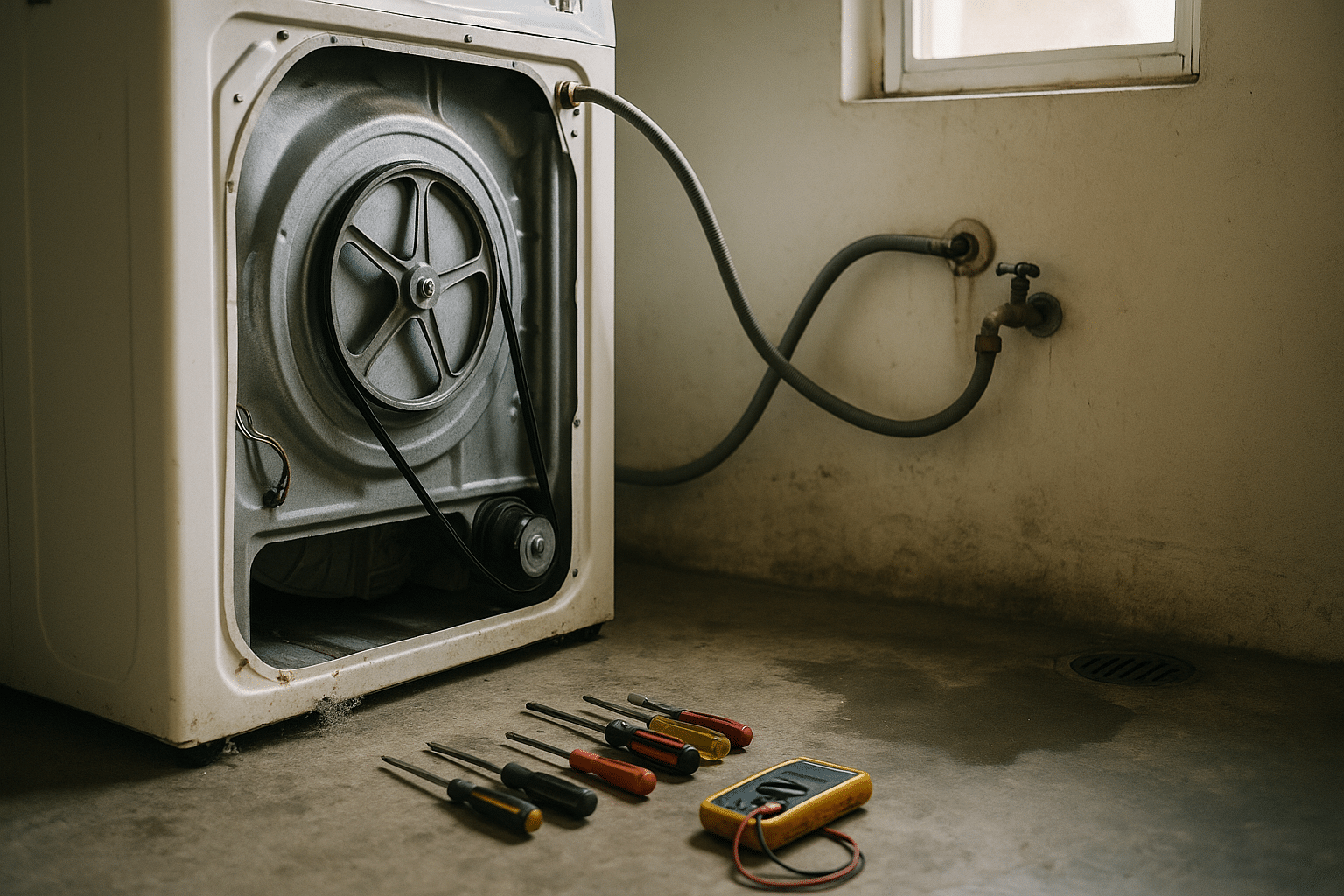

DIY Essentials: Tools, Parts, and Step-by-Step Examples

A compact, organized toolkit turns intimidating repairs into manageable projects. Prioritize tools that fit tight spaces and fasteners common to appliances. Core kit essentials include a #2 Phillips and flathead screwdriver, a set of nut drivers (1/4, 5/16, 3/8 inch), a socket set, Torx bits, a putty knife, needle-nose pliers, slip-joint pliers, hose clamp pliers, zip ties, a multimeter, a non-contact voltage tester, and a stiff brush for coil cleaning. Keep a headlamp handy for peering behind kick plates and into dim cabinets. For moving heavy units, an appliance dolly and furniture sliders protect floors and backs alike.

Stock frequently used consumables and parts:

– Replacement water and air filters, as specified for your model

– Universal rubber gaskets and O-rings for hoses and doors

– Thread seal tape, high-temp rated where appropriate

– A few thermal fuses and common-sized belts for your dryer model

– Stainless hose clamps and spare inlet hoses (consider braided steel)

– A compact tube of food-grade silicone for refrigerator door gaskets

Always verify compatibility by model and part number; a “close” fit can leak, bind, or overheat.

Try three confidence-building DIYs:

– Clean refrigerator condenser coils: unplug, pull the unit forward, pop off the lower grille, and use a coil brush plus a vacuum to remove lint and pet hair. This 15-minute task can trim energy use and restore cooling performance.

– Replace a dryer belt: unplug, open the top or front panel per your model’s service sheet, release the belt from the idler pulley and motor, route the new belt along the drum grooves, re-tension via the idler, and spin the drum by hand to confirm alignment before reassembly.

– Unclog a dishwasher filter and spray arms: remove the lower rack, twist out the filter, rinse debris, poke mineral build-up from spray arm holes with a wooden toothpick, and re-seat firmly. Run a hot cycle to validate spray patterns.

Respect limits. Microwaves contain capacitors that can hold dangerous charges; sealed refrigeration systems require specialized tools and certifications to open; gas connections must be leak-checked with soapy water and, ideally, a manometer. Check warranty terms—opening certain panels can void coverage. When in doubt, stop, document what you learned, and hand off to a professional with clear notes that speed the fix.

Repair vs Replace: A Practical Framework With Numbers

Decisions feel easier with a rubric. Start with the 50 percent rule: if a repair exceeds half the price of a comparable replacement and the appliance is past half its typical lifespan, lean toward replacement. If the repair is well under that threshold and the unit is younger or midlife, repair usually makes financial sense. Layer in energy use and reliability trends to refine your choice, and you’ll balance today’s invoice with tomorrow’s utility bills.

Run a quick payback example. Suppose an older refrigerator uses about 900 kWh per year while a newer efficient unit uses around 500 kWh. At $0.18 per kWh, the annual savings is roughly (900–500) × $0.18 = $72. If your current fridge needs a $300 repair and a comparable new one costs $1,100 delivered, here’s the comparison:

– Repair path: $300 now; no major energy change; risk of future repairs rises with age.

– Replace path: $1,100 now minus $72 per year in energy savings; simple payback about 15 years before utility savings offset the price difference, not accounting for maintenance.

If the existing unit is otherwise reliable and under 12 years old, repair seems reasonable; if it’s already 15 years old with recurring issues, replacement looks more attractive despite the slower payback.

Consider intangible and practical factors:

– Parts availability: discontinued controls or sealed-system components may be hard to source or pricey.

– Performance gaps: newer dishwashers may clean better with less water, while modern heat-pump dryers can cut energy use.

– Installation complexity: built-in appliances can add cabinetry and labor costs that alter the math.

– Environmental impact: extending a serviceable appliance delays waste; replacing an inefficient energy hog can reduce lifetime emissions.

Use a concise checklist:

– Age vs typical lifespan

– Quoted repair cost vs half of replacement price

– Energy use difference and estimated annual savings

– Frequency of recent failures and downtime costs

– Safety concerns (gas leaks, overheating, sparking)

– Warranty status and manufacturer support

Add numbers where you can. A decision with data is less guess and more guidance.

Hiring Help and Final Checklist: Turning a Plan Into Action

When a job calls for specialized tools, permits, or experience, a skilled technician can be a wise investment. Prepare like a partner, not a bystander. Gather the model and serial numbers, note the exact symptoms, capture photos or videos, and list any error codes. Clear a path to the appliance, secure pets, and ensure nearby outlets and valves are accessible. This preparation shaves diagnostic time and shows the technician you value clarity, which can translate into a smoother visit.

Choose a service provider with transparent practices. Look for clear pricing structures—either flat-rate menus or time-and-materials with published hourly rates—and a written diagnostic fee that’s credited toward repair if you proceed. Ask about warranty terms on parts and labor, and how they handle callbacks. Clarify whether they use original or high-quality aftermarket parts, how long parts typically take to arrive, and whether old components will be returned or shown to you for verification. Professionalism shows in little things: punctuality windows, clean drop cloths, and plain-language explanations.

Arrive with smart questions:

– What is the root cause, and how did you confirm it?

– Are there secondary parts likely to fail soon that make sense to replace together?

– What maintenance step could have prevented this, and what should I do differently?

– If I choose not to repair, what are the safe shutdown steps and disposal considerations?

– How long is the repair expected to last, based on the appliance’s age and condition?

Watch for red flags: vague diagnoses, pressure to replace without testing, refusal to provide written estimates, and reluctance to discuss warranty terms. Keep records of invoices, replaced parts, and maintenance dates; these notes help with warranty claims and future troubleshooting. For landlords or property managers, standardize a response playbook—documented steps, preferred vendors, and replacement thresholds—to cut downtime and cost variance.

Conclusion and next steps: Treat each appliance like a small business asset. Inspect routinely, clean vents and coils, replace inexpensive wear parts on schedule, and act early when performance slips. Use the decision framework to weigh repair against replacement with real numbers, not hunches. When the problem outgrows your toolkit, partner with a reputable technician and arrive prepared. Do this consistently, and your kitchen and laundry room will run quieter, safer, and more affordably—leaving your time and budget for the things that truly matter.